AiO Flex

The first disposable to feature all 304 Stainless Steel Wetted Materials

#notjustvapor

AiO Flex

The first disposable to feature all 304 Stainless Steel Wetted Materials

#notjustvapor

When your product is “Powered by

Blinc” your offering is future-proof

Certified “Powered by Blinc” is a short way of saying that the product has been manufactured to the highest international standards of safety and compliance with complete quality control and full traceability of the product, process and each sub-component across the entire value chain.

Verified Raw Materials

For redundancy and resiliency reasons, for each raw material used in our products, we have one or two major suppliers and two minor suppliers. These suppliers are fully vetted by our China-based Quality Control team. Providing an extra level of control, we audit these suppliers every six months in order to ensure continual improvement: documentation, production areas, QMS, and social compliance.

Regulatory Compliance

Powered by Blinc products are manufactured exclusively at Blinc-approved and vetted ISO9001:2015, ISO13485:2016, and food processing GMP certified facilities. Additionally, Powered by Blinc devices and components are certified or compliant with multiple standards like FDA Title 21 CFR, FDA CPG, UL8139, RoHS, CE, and FCC.

Rigorous Quality Control

With full control of the entire value chain and ISO level quality control systems in place at every step of the manufacturing process, Blinc has set the gold standard of quality and safety management for the cannabis vaping industry. This enables us to have full traceability of every product, subcomponent, and every process ensuring consistent delivery of a future-proof product to our customers.

Free of Contaminants

Vape safety is in our genes, therefore since day 1 Blinc has been focused on everything from clean and leach free raw materials all the way to how the concentrates interact with these materials and what the emissions are at temperatures multiplied by end-user vaping habits. With ongoing studies and testing, we ensure that Blinc products are the safest on the market, with ample data to back up the statement.

Blinc products are guarnateed compliant with key international standards

Our Guarantee

Complete Traceability

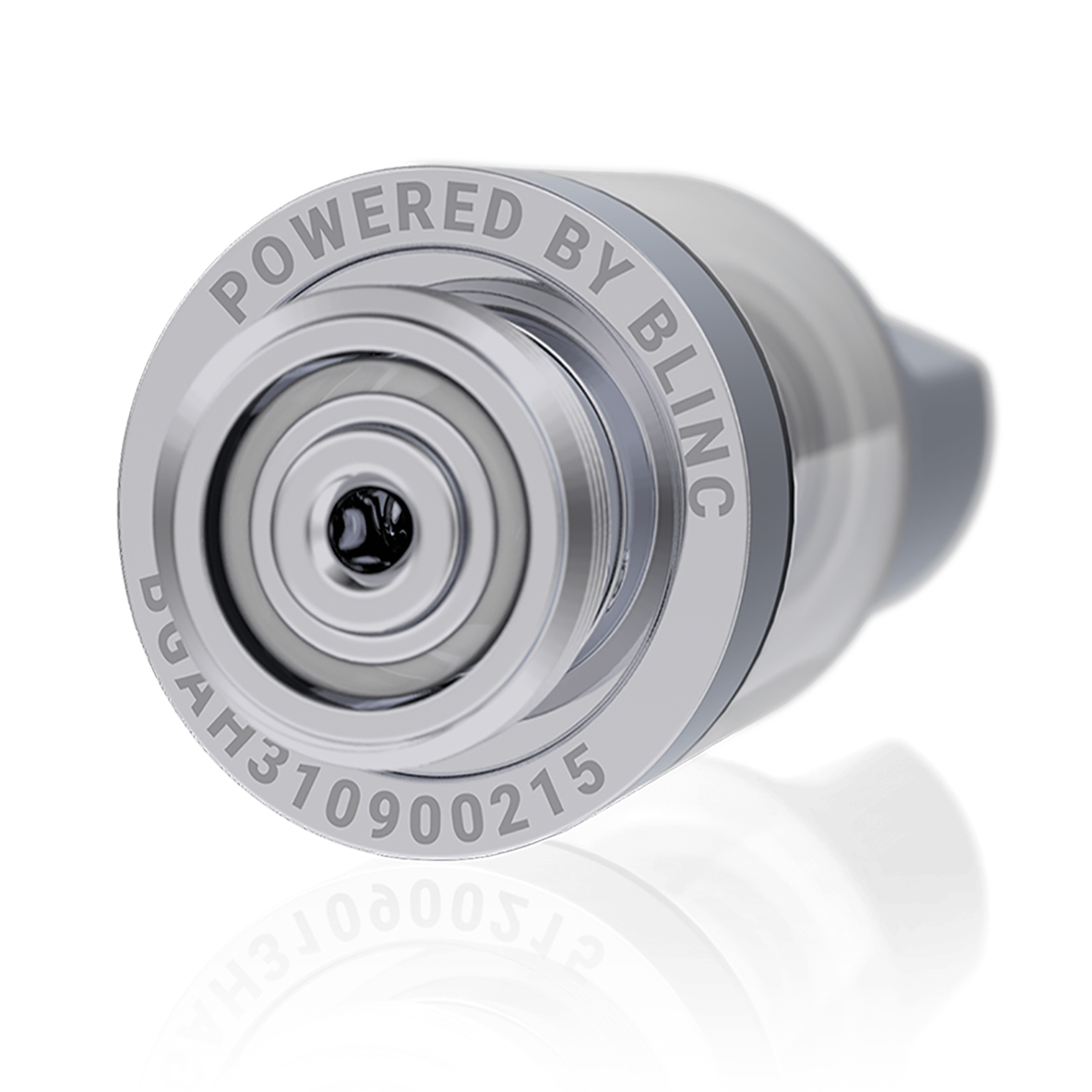

The Powered by Blinc serial number ensures complete traceability of each “batch” of goods that were made together in the same manufacturing run and produced using the same materials. Each batch is given a specific number and all of the goods produced at once get stamped with this number. If there is an issue with a specific product, the batch number allows us to trace the product back to a particular batch and take corrective action on that specific batch of products with certainty.

Powered by Blinc sample serial number

In this example, we can clearly identify that this is a cartridge that has been manufactured on July 18th 2020 in production facility 3, that it is a 0.5ml, 1.2 ohm, silver, V12 with a white ceramic push and lock mouthpiece made for client number 900.

Quality Control & Assurance

Blinc-China team ensures on-site quality

control & clear reporting - so there’s no surprises

Blinc’s China office, strategically located in Guangdong Province has been established to ensure on the ground quality and safety management. Headed up by a former quality control director of Lowes and Home Depot, our China quality control team ensures that our approved suppliers and manufacturers upkeep the rigorous standards set in place by Blinc. Before any product is produced, we work with the client to develop a quality management protocol with clear guidelines on quality and defect matrix, in order to ensure that the end product meets expectations. With a clear understanding of the entire value

chain and a commitment to the company’s promise, Blinc China QC team controls the entire process, starting with vetted sub-component suppliers, initial production checks, rigorous DUPRO (during production) protocols as well as final quality control. Upon completion of any production run, a detailed report with all findings is submitted to our client for approval, and only then the product is shipped through Blinc-approved forwarders. This multi-step control process ensures clear objectives, precise expectations, and a high-quality consistent end product, with replicable results every time.

Quality Control & Assurance

Blinc-China team ensures on-site quality

control & clear reporting - so there’s no surprises

Blinc’s China office, strategically located in Guangdong Province has been established to ensure on the ground quality and safety management. Headed up by a former quality control director of Lowes and Home Depot, our China quality control team ensures that our approved suppliers and manufacturers upkeep the rigorous standards set in place by Blinc. Before any product is produced, we work with the client to develop a quality management protocol with clear guidelines on quality and defect matrix, in order to ensure that the end product meets expectations. With a clear understanding of the entire value

chain and a commitment to the company’s promise, Blinc China QC team controls the entire process, starting with vetted sub-component suppliers, initial production checks, rigorous DUPRO (during production) protocols as well as final quality control. Upon completion of any production run, a detailed report with all findings is submitted to our client for approval, and only then the product is shipped through Blinc-approved forwarders. This multi-step control process ensures clear objectives, precise expectations, and a high-quality consistent end product, with replicable results every time.